Our Trucks. The new Arocs. Construction and All-Wheel Drive (AWD) haulage.

THE SMART POWERHOUSE FOR THE CONSTRUCTION SECTOR.

Regardless of whether it is a rigid truck, concrete mixer, support vehicle or spreader: the on-road and all-wheel variants of the new Arocs provide an especially robust, resilient vehicle that is optimally prepared for use in a wide range of construction haulage applications.

THE AROCS AT A GLANCE.

Robustness.

The robustness and load-bearing capacity of the Arocs are already reflected in the application-specific cabs, both in the durable, resistant cab bodyshell and in the powerful design.

Efficiency.

Unites what belongs together: RoadEfficiency combines low overall costs with high levels of safety and high vehicle use. For even more transport efficiency.

Reliability.

During the construction of our trucks, we always use the strictest quality standards: Real-life requirements. Or in short: Your requirements.

Technical data.

With its economical, reliable Euro VI engines as well as many cab variants, the Arocs provides a solution for a wide range of requirements.

Highlights and other facts.

With Mercedes-Benz Genuine Accessories, the Arocs provides numerous individual configurations.

Features

The Arocs are vehicles which use fuel efficiently. Because the lower the fuel consumption, the lower the overall costs.

Our trucks are especially economical vehicles at your disposal. However, the premium Mercedes-Benz services, and the attractive residual value at the end of the service life, also ensure low costs.

Arrive safely - with innovative assistance systems to help improve driving safety, such as Active Brake Assist 5, drivers are actively supported, the vehicle and the load are treated with sufficient care and efficiency is increased. On every journey.

Intelligent networking of vehicle, Mercedes-Benz Service and your transport company enable vehicle use, vehicle capacity and the efficiency of your logistics processes to be increased noticeably.

The Predictive Powertrain Control system provides a simple means of saving even more fuel with the Arocs. On highways, roads and city streets alike.

Especially reliable - thanks to over 110 years of experience in vehicle construction.

GIVING YOU THAT EXTRA EDGE.

During the construction of our trucks, we always use the strictest quality standards: real-life requirements. Or in short: your requirements.

For us, this means providing you with trucks that operate without a hitch, even in extreme conditions and in difficult terrain. In other words: “Trucks you can trust”.

As your partner who helps you to master your daily transport tasks efficiently, we will continue to put our all into ensuring you have reliable vehicles at your disposal. With the wealth of experience that comes from more than 110 years in vehicle manufacturing. With trucks boasting robust components that have been tried and tested thousands of times and equipment designed to cope with the topographic and climatic conditions that prevail where the vehicles are to be operated. This applies to engines, gearshifts, transmissions and drive axles as well as frames, chassis, suspension and cabs, as a reliable truck can only ever be the sum of its reliable individual components.

From the windscreen wiper to the brake lamp - at Mercedes-Benz, reliability is built-in as standard. This comes from a recognition that every component is important - right from the design and development stage.

The Development and Testing Centre in Worth. High reliability and durability are Mercedes-Benz hallmarks. At the Development and Testing Centre in Worth, Germany a workforce of around 300 is dedicated to ensuring your vehicles offer reliable performance.

The reliability of a truck is determined in the development stage. To this end, defined reliability targets are set for each individual part and assembly and for the truck as a whole.

Work at the Development and Testing Centre in Worth, Germany draws on the extensive experience available here, applying the very latest scientific methods and focusing on our customers' expectations. In addition everything we develop is subjected to extreme stress testing. From the functional testing of individual components through to endurance trials on the test track to driving trials, we test all aspects of our trucks' robustness, durability and reliability.

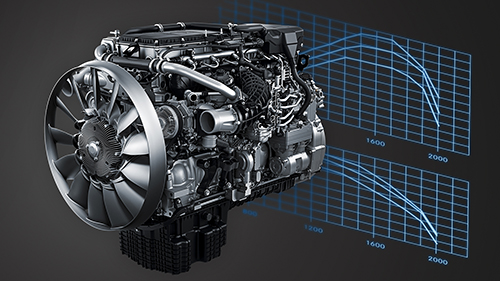

All engines offer a particularly robust, durable design, a high degree of reliability and an extended service life.

All components of the drivetrain are ideally matched and produced exclusively at Mercedes-Benz.

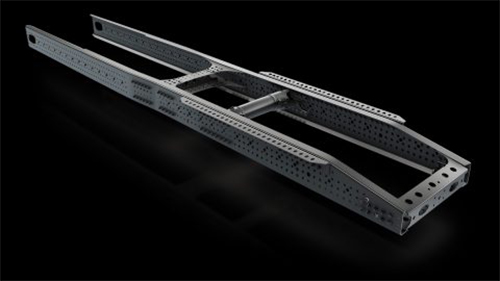

Road and construction site use impose different requirements on the frame, chassis, suspension and brakes. Accordingly, our trucks are equipped with components required for a wide variety of jobs.

Anti-corrosion protection for the cabs through the use of galvanised panels, robust frames protected from corrosion by means of cathodic dip priming, a transmission oil cooler for reduced thermal stress, efficient air filters and long maintenance intervals are all factors that contribute to a high level of reliability.

When it comes to maintenance and repair, Mercedes-Benz GenuineParts are designed to help keep you safe. They are developed specifically for the given job and have confirmed their quality in numerous tests and thousands of kilometres of vehicle trials.

As a cost-effective and environmentally friendly alternative, the extensive portfolio of remanufactured parts offers the usual high quality and tested safety of Mercedes-Benz, at attractive prices.

MORE FACTS AT A GLANCE.

Genuine Accessories.

In this section, you can learn how the comprehensive range of Mercedes-Benz Genuine Accessories offers broad scope for individual solutions. Additionally, check back for regular exciting updates and news regarding the Arocs.

With the Arocs you are well prepared for construction transport operations. To enable you to tailor the truck even more effectively to your personal vision of the perfect construction vehicle, there is a comprehensive range of Mercedes-Benz Genuine Accessories: for numerous individual configurations.

The Arocs isn't just a head-turner on the road. It also makes for a pleasant desktop background on your computer.

The Arocs Euro VI engines: future-oriented technology, up to 460 kW (625 hp) and 3,000 Nm maximum torque.

Whether for everyday freight jobs, on the construction site or tasks with frequent overnight stays - Arocs cabs impress with their robust, durable design.

Whether it is wheelbase, engine or cab variants, the Arocs provides an especially robust, resilient vehicle that is optimally prepared for use for a wide range of construction haulage tasks.

Others see a construction site, it sees a playground.

OTHERS SEE A CONSTRUCTION SITE, IT SEES A PLAYGROUND. THE NEW AROCS.

The Arocs' robustness and load-bearing capacity are already reflected in the application-specific cabs, both in the durable, resistant cab bodyshell and in the powerful design. A high standard of driving comfort and ergonomics is provided by three different cockpit variants with multifunction steering wheel, the PowerShift 3 automated transmission and a broad range of wide and comfortable seats, for example. Unique connectivity and equipment such as the new MirrorCam and the electronic parking brake further enhance driving comfort and ergonomics.

The Arocs cabs boast impressive practicality, robustness and resilience. At a glance. In every little detail. And always when it counts most.

During the first test drive and after countless trips: the Arocs cabs show what distinguishes a modern workplace. With exemplary ergonomics, a high level of functionality and many new and practical details that simply make the tough job easier.

The powerful, robust Arocs engines incorporate advanced, efficient Euro VI technology. Above all, they deliver the power you need for the tough jobs in construction transport and the PowerShift 3 automated gearshift boasts high driving comfort, precise gear selection, efficient power transmission and enhanced1 handling.

Resilience and robustness are defining features of the Arocs. This is demonstrated in the trucks structural design, including the frame, chassis, and suspension.